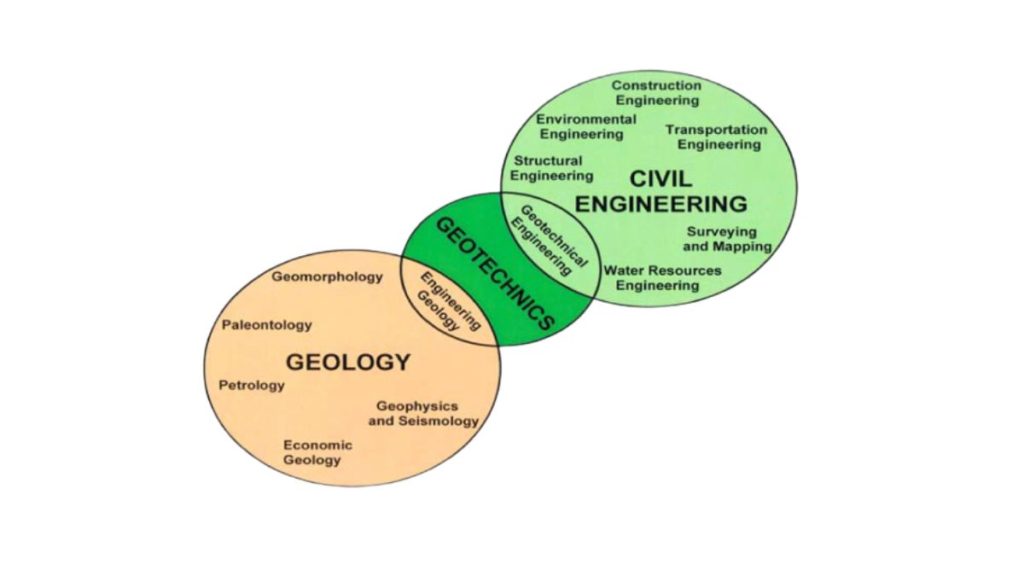

What are Deep Foundations?

Deep foundations are employed when the soil strata immediately beneath the structure are not capable of supporting the load with tolerable settlement or adequate safety against shear failure. Merely extending the level of support to the first hard stratum is not sufficient, although this is a common decision that is reached. Instead, the deep foundation must be engineered in the same way as the shallow foundation so that the soil strata below remain safe and free of deleterious settlement.

Two general forms of deep foundations are recognised:

- Pile foundation

- Pier, caisson or well foundation.

Piles are relatively long, slender members that are driven into the ground or cast-insitu. Piers, caissons or wells are larger, constructed by excavation and are sunk to the required depth; these usually permit visual examination of the soil or rock on which they rest. In effect they are deep spread footings or mats. They are normally used to carry very heavy loads such as those from bridge piers or multi-storeyed buildings. A sharp distinction between piles and piers is impossible because some foundations combine features of both.

Piles have been used since prehistoric times. The Neolithic inhabitants of Switzerland, 12,000 years ago, drove wooden poles in the soft bottoms of shallow lakes and on them erected their homes, high above marauding animals and warring neighbours. Pile foundations were used by Romans; Vitruvius (59 A.D.) records the use of such foundations. Today, pile foundations are much more common than any other type of deep foundation, where the soil conditions are unfavourable.

CLASSIFICATION OF PILES (Deep foundations)

Piles may be classified in a number of ways based on different criteria:

1. Function or action

2. Composition and material

3. Installation

Classification Based on Function or Action

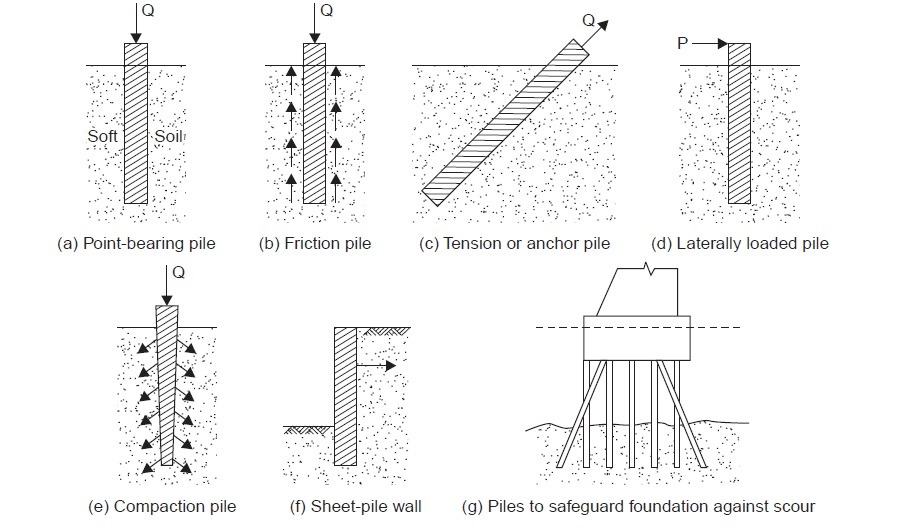

Piles may be classified as follows based on the function or action:

End-bearing piles

Used to transfer load through the pile tip to a suitable bearing stratum, passing soft soil or water.

Friction piles

Used to transfer loads to a depth in a frictional material by means of skin friction along the surface area of the pile.

Tension or uplift piles

Used to anchor structures subjected to uplift due to hydrostatic pressure or to overturning moment due to horizontal forces.

Compaction piles

Used to compact loose granular soils in order to increase the bearing capacity. Since they are not required to carry any load, the material may not be required to be strong; in fact, sand may be used to form the pile. The pile tube, driven to compact the soil, is gradually taken out and sand is filled in its place thus forming a ‘sand pile’.

Anchor piles

Used to provide anchorage against horizontal pull from sheetpiling or water.

Fender piles

Used to protect water-front structures against impact from ships or other floating objects.

Sheet piles

Commonly used as bulkheads, or cut-offs to reduce seepage and uplift in hydraulic structures.

Batter piles

Used to resist horizontal and inclined forces, especially in water front structures.

Laterally-loaded piles

Used to support retaining walls, bridges, dams, and wharves and as fenders for harbour construction.

Classification Based on Material and Composition

Piles may be classified as follows based on material and composition:

Timber piles

These are made of timber of sound quality. Length may be up to about 8 m; splicing is adopted for greater lengths. Diameter may be from 30 to 40 cm. Timber piles perform well either in fully dry condition or submerged condition. Alternate wet and dry conditions reduce the life of a timber pile; to overcome this, creosoting is adopted. Maximum design load is about 250 kN.

Steel piles

These are usually H-piles (rolled H-shape), pipe piles, or sheet piles (rolled sections of regular shapes). They may carry loads up to 1000 kN or more.

Concrete piles

These may be ‘precast’ or ‘cast-in-situ’. Precast piles are reinforced to withstand handling stresses. They require space for casting and storage, more time to cure and heavy equipment for handling and driving.

Cast-in-situ piles are installed by pre-excavation, thus eliminating vibration due to driving and handling. The common types are Raymond pile, Mac Arthur pile and Franki pile.

Composite piles

These may be made of either concrete and timber or concrete and steel. These are considered suitable when the upper part of the pile is to project above the water table. Lower portion may be of untreated timber and the upper portion of concrete. Otherwise, the lower portion may be of steel and the upper one of concrete.

Classification Based on Method of Installation

Piles may also be classified as follows based on the method of installation:

Driven piles

Timber, steel, or precast concrete piles may be driven into position either vertically or at an inclination. If inclined they are termed ‘batter’ or ‘raking’ piles. Pile hammers and pile-driving equipment are used for driving piles.

Cast-in-situ piles

Only concrete piles can be cast-in-situ. Holes are drilled and these are filled with concrete. These may be straight-bored piles or may be ‘under-reamed’ with one or more bulbs at intervals. Reinforcements may be used according to the requirements.

Driven and cast-in-situ piles

This is a combination of both types. Casing or shell may be used. The Franki pile falls in this category.

USE OF PILES (Deep foundations)

The important ways in which piles are used are as follows:

- To carry vertical compressive loads,

- To resist uplift or tensile forces, and

- To resist horizontal or inclined loads.

Bearing piles are used to support vertical loads from the foundations of buildings and bridges. The load is carried either by transferring to the incompressible soil or rock below through soft strata, or by spreading the load through soft strata that are incapable of supporting concentrated loads from shallow foootings. The former type are called point-bearing piles, while the latter are known as friction-piles.

Tension piles are used to resist upward forces in structures subjected to uplift, such as buildings with basements below the ground water level, aprons of dams or buried tanks. They are also used to resist overturning of walls and dams and for anchors of towers, guywires and bulkheads.

Laterally loaded piles support horizontal or inclined forces such as the foundations of retaining walls, bridges, dams, and wharves and as fenders in harbour construction.

In case the lateral loads are of large magnitude they may be more effectively resisted by batter piles, driven at an inclination. Closely spaced piles or thin sheet piles are used as cofferdams, seepage cut-offs and retaining walls. Piles may be used to compact loose granular soils and also to safeguard foundations against scouring.

PILE CAPACITY

The ultimate bearing capacity of a pile is the maximum load which it can carry without failure or excessive settlement of the ground. The allowable load on a pile is the load which can be imposed upon it with an adequate margin of safety; it may be the ultimate load divided by a suitable factor of safety, or the load at which the settlement reaches the allowable value.

The bearing capacity of a pile depends primarily on the type of soil through which and/ or on which it rests, and on the method of installation. It also depends upon the cross-section and length of the pile.

The pile shaft is a structural column that is fixed at the point and usually restrained at the top. The elastic stability of piles, or their resistance against buckling, has been investigated both theoretically and by load tests (Bjerrum, 1957). Both theory and experience demonstrate that buckling rarely occurs because of the effective lateral support of the soil; it may occur only in extremely slender piles in very soft clays or in piles that extend through open air or water.

Therefore, the ordinary pile in sand or clay may be designed as though it were a short column. The pile transfers the load into the soil in two ways. Firstly, through the tip-in compression, termed ‘end-bearing’ or ‘point-bearing’; and, secondly, by shear along the surface, termed ‘skin friction’. If the strata through which the pile is driven are weak, the tip resting on a hard stratum transfers most part of the load by end-bearing; the pile is then said to be an endbearing pile. Piles in homogeneous soils transfer the greater part of their load by skin friction, and are then called friction piles; however, nearly all piles develop both end-bearing and skin friction.

The following is the classification of the methods of determining pile capacity:

- Static analysis

- Dynamic analysis

- Load tests on pile

- Penetration tests

The first two are theoretical approaches and the last two are field or practical approaches.

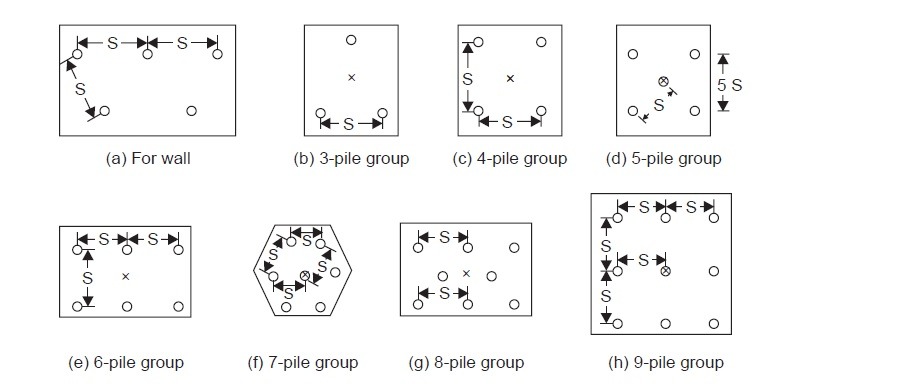

PILE GROUPS

A structure is never founded on a single pile. Piles are ordinarily closely spaced beneath structures; consequently, the action of the entire pile group must be considered. This is particularly important when purely friction piles are used.

The bearing capacity of a pile group is not necessarily the capacity of the individual pile multiplied by the number of piles in the group; the phenomenon by virtue of which this discrepancy occurs is known as ‘Group action of piles’.

DESIGN OF PILE FOUNDATIONS

The design of a pile foundation consists of assuming a design, then checking the proposed design for safety and revising it until it is satisfactory. The final design is selected on the basis of cost and time available for construction.

Sometimes piles may be valueless in some locations and may be even harmful under certain circumstances. For example, a layer of reasonably firm soil over a deep stratum of soft soil might act as a natural mat to distribute the load of a shallow footing. The driving of piles into the firm layer might break it up or remould it. The result could be a concentration of stress in the soft stratum, leading to excessive settlement.

CONSTRUCTION OF PILE FOUNDATIONS

The construction of a pile foundation involves two steps, namely the installation of piles and the making of pile caps. The second step is relatively simple and is similar to the construction of footings.

Installation of piles would depend upon whether they are driven or cast-in-place. Some details regarding the equipment required to install piles by driving them into soil have already been given. Water jetting is used to assist penetration of the piles.

Cast-in-place piles are mostly concrete piles of standard types such as the Raymond pile and the Franki pile, so called after the piling firms which standardised their construction.

Damage due to improper driving may be avoided if driving is stopped when the penetration reaches the desired resistance.

Some degree of tolerance in alignment has to be permitted since piles can never be driven absolutely vertical and true to position.

A pile may be considered defective if it is damaged by driving or is driven out of position, is bent or bowed along its length. A defective pile must be withdrawn and replaced by another pile. It may by left in place and another pile may be driven adjacent to it. Pile driving may induce subsidence, heave, compaction, and disturbance of the surrounding soil. These effects are to be carefully studied so as to understand their bearing on the capacity of the pile.

[…] More read click on image… […]