How are deep displacements measured?

There are two widely used ways, which are:

- Inclinometers

- Extensometers

Inclinometers

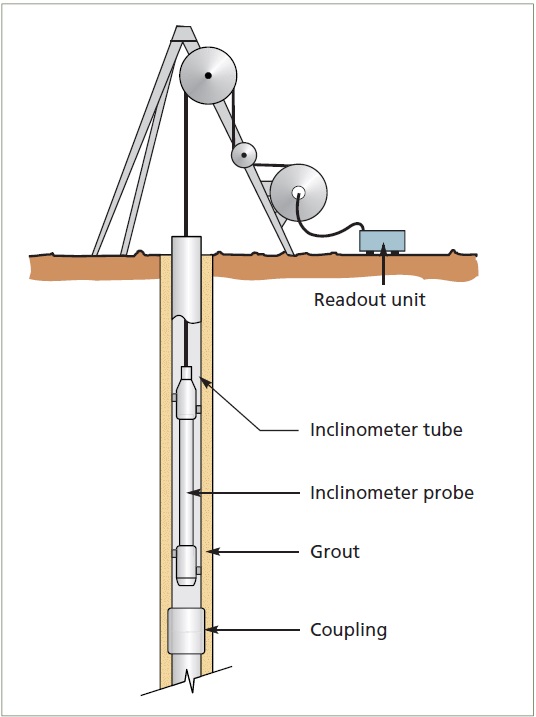

Inclinometers are one of the main methods for investgating landslides and for general control of transversal displacements in boreholes. Inclinations at various points inside a borehole are measured by means of a sonde that transmits an electric signal proportional to the angle of slope (Figures 1 and 2).

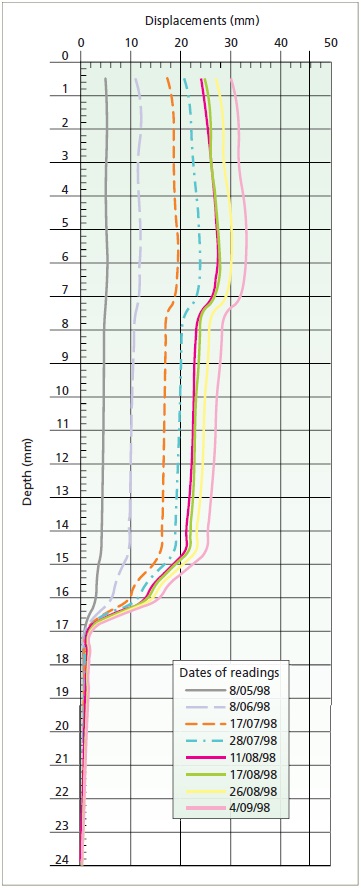

Transversal displacements in a borehole can be recorded and quantified from differences between measurements taken at different points and the times at which these are taken. Figure 3 shows an example of readings taken by an inclinometer in which two failure surfaces are identified at depths of 7.5 and 17 m.

Inclinometers may have an electrical resistance, vibrating wire sondes or servoaccelerometers. This last type can measure rotation precisely to 2 x10-4 rad. It is important to make sure that the inclinometer is installed to below any areas of possible movement so it can straddle them.

Extensometers

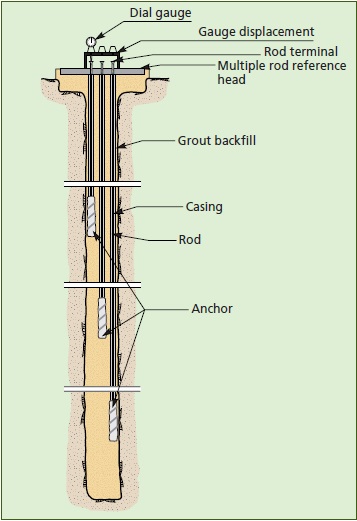

This instrument can measure movements between two points, one at the top of the borehole and the other inside it, where the extensometer is anchored.

Displacements at the anchor points are transmitted to the top of the borehole by wires and rods. Measurement is by either mechanical or electrical procedures. The rod extensometer is used for lengths under 40 m (Figures 4 and 5) and the wire extensometer for lengths over 60 m.

Displacements in shafts and boreholes

Other methods used to detect displacements or estimate the depth of sliding surfaces include:

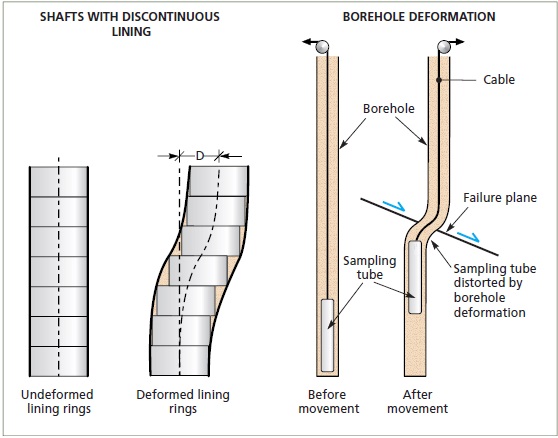

— Observing the deformation in large diameter bores or shafts with segmented casing where the depth of the deformation or failure can be measured approximately.

— Inserting a “telltale”, a piece of metal tubing 25–40 cm long, into the bottom of a cased borehole to measure the depth at which the tube is intercepted because the borehole is deformed or blocked by ground displacements (Figure 6).