Understanding the Mohs Hardness Scale

Introduction:

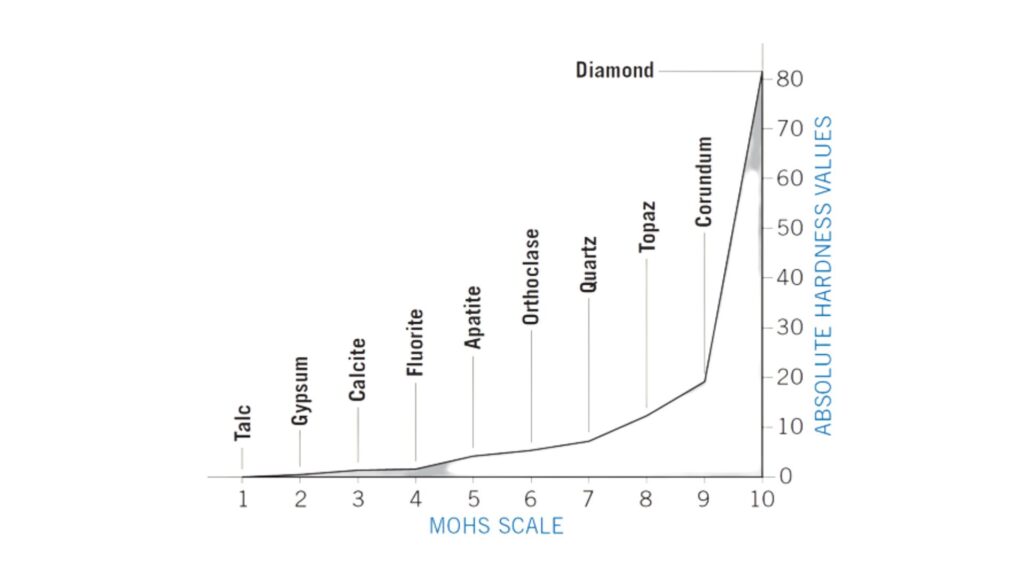

The realm of geology and material science is marked by a fascinating metric known as the Mohs Hardness Scale. This scale, named after its creator Friedrich Mohs, serves as a cornerstone in determining the relative hardness of minerals. With its origins dating back to the early 19th century, the scale’s significance extends beyond academia, finding practical applications in various industries.

The Mohs Hardness Scale Explained:

The Mohs Hardness Scale is a numerical framework employed to measure the hardness of minerals based on their ability to scratch each other. Ranging from 1 to 10, the scale places talc at the lowest end, as the softest mineral, and diamond at its zenith, representing the hardest. Friedrich Mohs, a German mineralogist, introduced this system in 1812. By utilizing common materials like fingernails, glass, and specific minerals, the scale establishes a hierarchy of mineral hardness, crucial in mineral identification and characterization.

Mohs Hardness Scale

| Mineral Image | Hardness Level | Mineral Name | Common Object Example |

|---|---|---|---|

|

10 | Diamond | Diamond |

|

9 | Corundum | Tungsten Carbide |

|

8 | Topaz | Scratch Plate |

|

7 | Quartz | Hardened Steel |

|

6 | Orthoclase | Steel File |

|

5 | Apatite | Glass Plate |

|

4 | Fluorite | Knife Blade |

|

3 | Calcite | Copper Coin |

|

2 | Gypsum | Fingernail |

|

1 | Talc | Fingernail |

Origins and Development:

Attributed to Friedrich Mohs, the scale emerged during the early 19th century when mineral testing lacked a standardized method. Mohs sought a practical approach, and his scale addressed this need. Born in 1773, Mohs was a prolific mineralogist who aimed to simplify the complex realm of mineral analysis. His innovation swiftly gained traction due to its simplicity and effectiveness, laying the foundation for modern mineralogy.

Applications Across Industries:

The Mohs Hardness Scale’s significance reverberates across diverse industries. In the field of geology, it aids in mineral identification during geological surveys. In construction, the scale guides the selection of materials for various applications, ensuring durability. Moreover, jewelers and gemologists utilize the scale to evaluate gemstone resilience and potential for wear. Additionally, archaeologists employ the scale to understand tools and artifacts’ historical uses and to decipher their cultural contexts.

Conclusion:

In the grand tapestry of mineral science, the Mohs Hardness Scale stands as an enduring legacy of Friedrich Mohs’ ingenuity. Its simple yet effective methodology has provided a universal language for assessing mineral hardness, transcending academic boundaries. From geology to jewelry-making, this scale’s influence is palpable, showcasing its vital role in understanding the physical properties of minerals that shape our world.