Pressuremeter test

The pressuremeter test is carried out to assess deformability inside a borehole. Equal increments of radial pressure are applied to an expandable cylindrical membrane (the pressuremeter) in the borehole. Dilation induced in the surrounding ground is measured after each pressure step. Once the maximum allowable pressure is reached, deflation of the pressuremeter is carried out step by step and deformations during deflation are measured. Pressure is applied through a rubber sheath, using water or gas. Most equipment works with pressures of less than 10 MPa but some allow pressures up to 20 MPa to be applied (Figure 1).

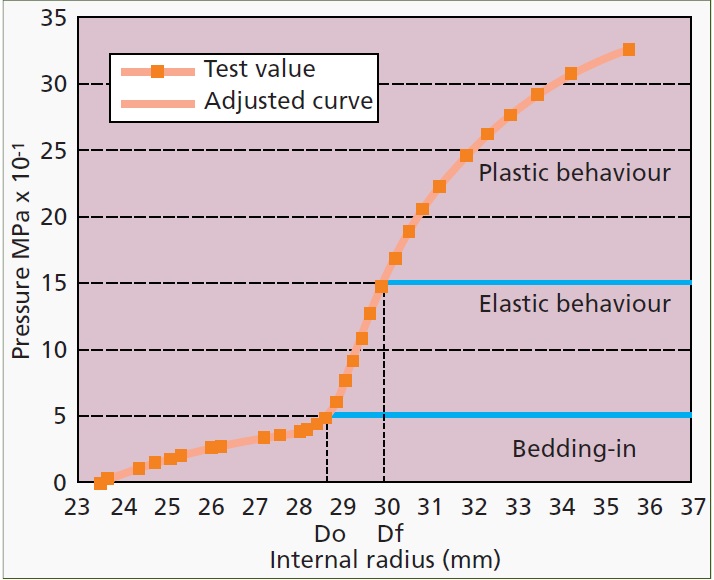

Depending on the type and characteristics of the soil being tested, the following phases can be identified in the pressure-deformation curve obtained (Figure 2):

an initial phase, when the probe enters into contact with the sides of the borehole; a linear elastic phase, corresponding to the elastic behaviour of the soil; and a plastic or irrecoverable deformation phase leading up to soil failure. From this curve it is possible to calculate the yield pressure PF, or pressure at which the material ceases to behave elastically, and the limit pressure PL, or pressure at which the ground shears and no longer accepts pressure increases. Finally, the pressiometric deformation modulus, EP, is obtained from the following expression:

Ep = (1 + ν) M ⋅ r

where ν is Poisson’s ratio obtained in laboratory tests, M is the stiffness of the ground, calculated from the slope of the elastic section of the pressiometric curve, and r is the borehole radius.