Rock Mass Rating calculation (RMR)

When was the Rock Mass Rating system created?

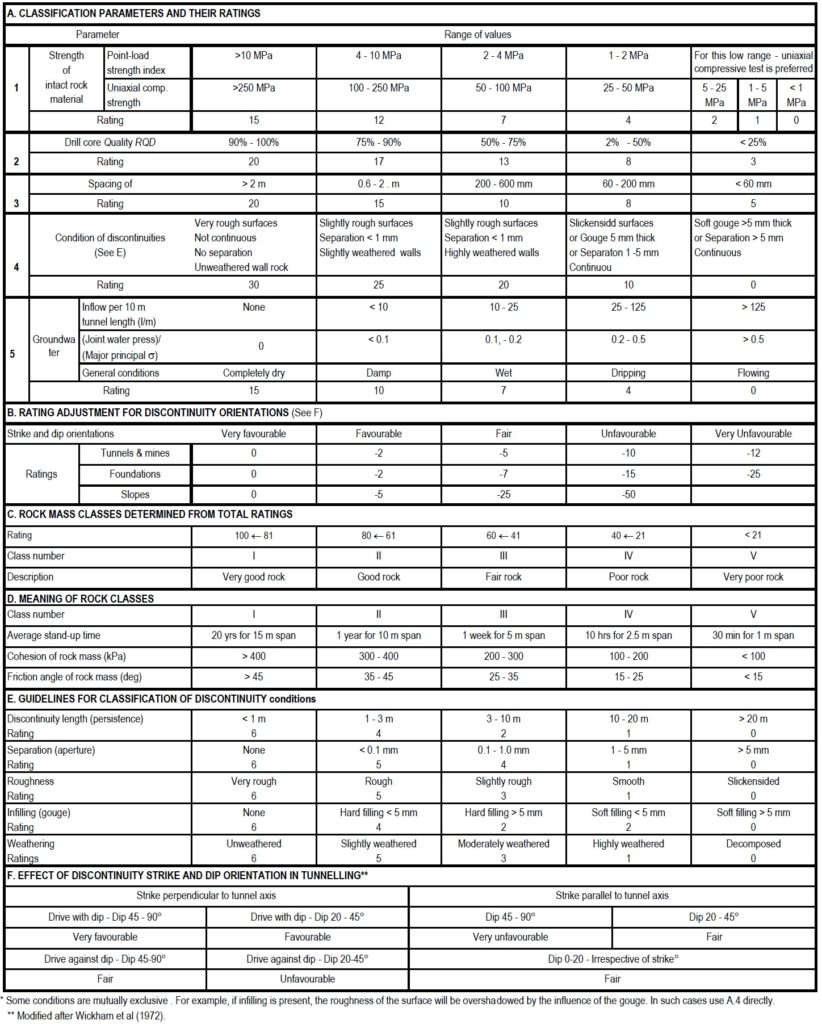

Bieniawski (1976) published the details of a rock mass classification called the Geomechanics Classification or the Rock Mass Rating (RMR) system. Over the years, this system has been successively refined as more case records have been examined and the reader should be aware that Bieniawski has made significant changes in the ratings assigned to different parameters. The discussion which follows is based upon the 1989 version of the classification (Bieniawski, 1989). Both this version and the 1976 version deal with estimating the strength of rock masses. The following six parameters are used to classify a rock mass using the RMR system:

1. Uniaxial compressive strength of rock material.

2. Rock Quality Designation (RQD).

3. Spacing of discontinuities.

4. Condition of discontinuities.

5. Groundwater conditions.

6. Orientation of discontinuities.

In applying this classification system, the rock mass is divided into a number of structural regions and each region is classified separately. The boundaries of the structural regions usually coincide with a major structural feature such as a fault or with a change in rock type. In some cases, significant changes in discontinuity spacing or characteristics, within the same rock type, may necessitate the division of the rock mass into a number of small structural regions.

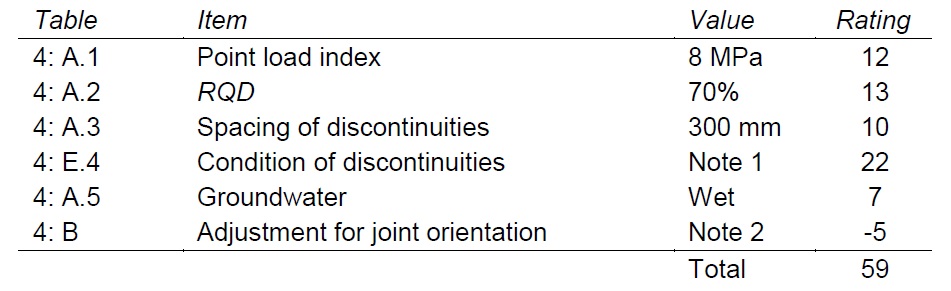

The Rock Mass Rating system is presented in Table, giving the ratings for each of the six parameters listed above. These ratings are summed to give a value of RMR. The following example illustrates the use of these tables to arrive at an RMR value.

A tunnel is to be driven through slightly weathered granite with a dominant joint set dipping at 60o against the direction of the drive. Index testing and logging of diamond drilled core give typical Point-load strength index values of 8 MPa and average RQD values of 70%. The slightly rough and slightly weathered joints with a separation of < 1 mm, are spaced at 300 mm. Tunnelling conditions are anticipated to be wet.

Note 1. For slightly rough and altered discontinuity surfaces with a separation of < 1 mm, Table. A.4 gives a rating of 25. When more detailed information is available, Table.E can be used to obtain a more refined rating. Hence, in this case, the rating is the sum of: 4 (1-3 m discontinuity length), 4 (separation 0.1-1.0 mm), 3 (slightly rough), 6 (no infilling) and 5 (slightly weathered) = 22. Note 2. Table.F gives a description of ‘Fair’ for the conditions assumed where the tunnel is to be driven against the dip of a set of joints dipping at 60o. Using this description for ‘Tunnels and Mines’ in Table.B gives an adjustment rating of -5.

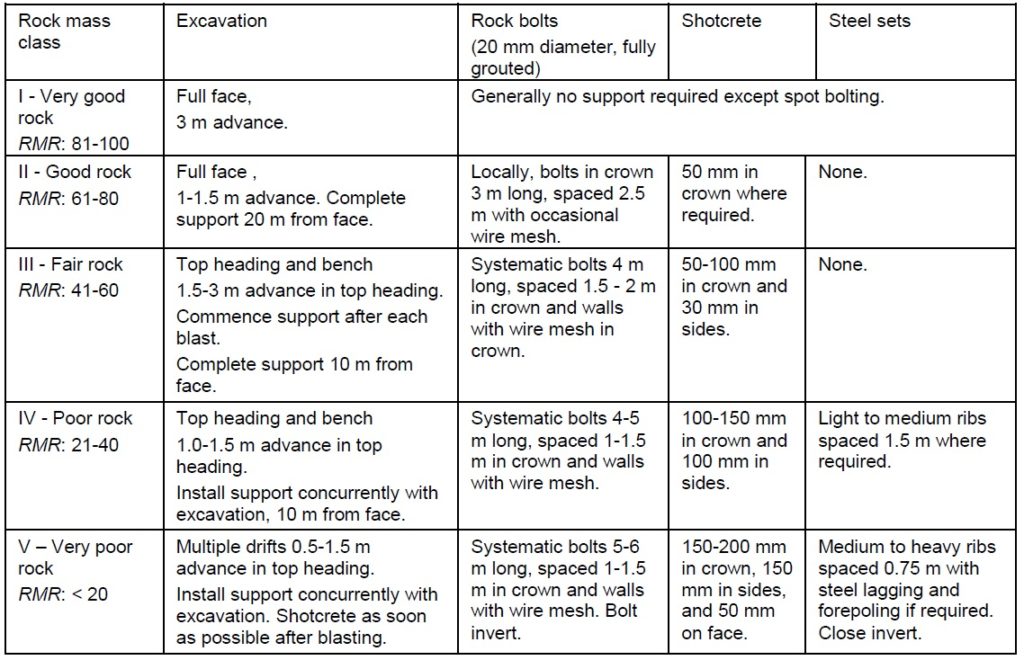

Bieniawski (1989) published a set of guidelines for the selection of support in tunnels in rock for which the value of RMR has been determined. These guidelines are reproduced in Table. Note that these guidelines have been published for a 10 m span horseshoe shaped tunnel, constructed using drill and blast methods, in a rock mass subjected to a vertical stress < 25 MPa (equivalent to a depth below surface of <900 m). For the case considered earlier, with RMR = 59, Table suggests that a tunnel could be excavated by top heading and bench, with a 1.5 to 3 m advance in the top heading. Support should be installed after each blast and the support should be placed at a maximum distance of 10 m from the face. Systematic rock bolting, using 4 m long 20 mm diameter fully grouted bolts spaced at 1.5 to 2 m in the crown and walls, is recommended.

Wire mesh, with 50 to 100 mm of shotcrete for the crown and 30 mm of shotcrete for the walls, is recommended. The value of RMR of 59 indicates that the rock mass is on the boundary between the ‘Fair rock’ and ‘Good rock’ categories. In the initial stages of design and construction, it is advisable to utilise the support suggested for fair rock. If the construction is progressing well with no stability problems, and the support is performing very well, then it should be possible to gradually reduce the support requirements to those indicated for a good rock mass. In addition, if the excavation is required to be stable for a short amount of time, then it is advisable to try the less expensive and extensive support suggested for good rock. However, if the rock mass surrounding the excavation is expected to undergo large mining induced stress changes, then more substantial support appropriate for fair rock should be installed. This example indicates that a great deal of judgement is needed in the application of rock mass classification to support design.

It should be noted that Table has not had a major revision since 1973. In many mining and civil engineering applications, steel fibre reinforced shotcrete may be considered in place of wire mesh and shotcrete.

Rock Mass Rating mobile application

Geologists / geotechnical engineers use the stated categorization of rock mass every day when building tunnels, securing slopes, etc.

To facilitate the work in the field, our engineers created a mobile application.

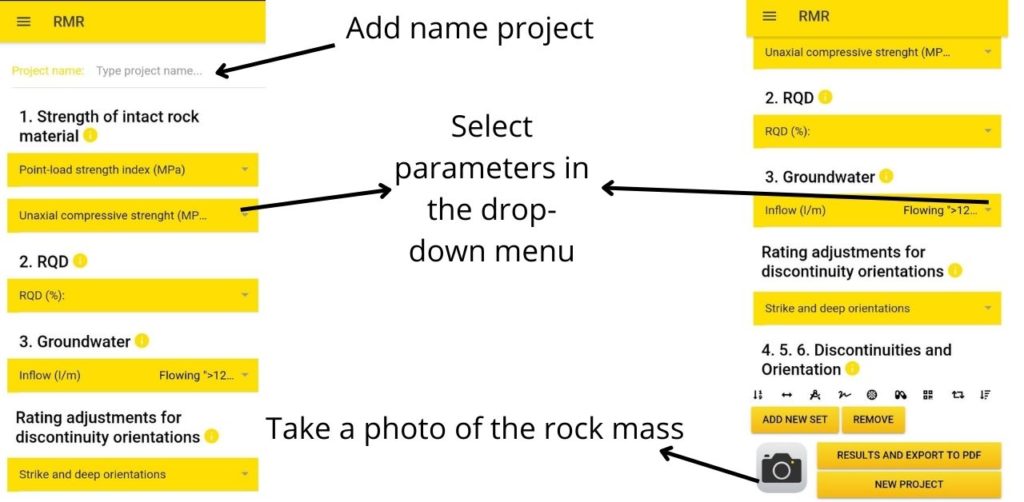

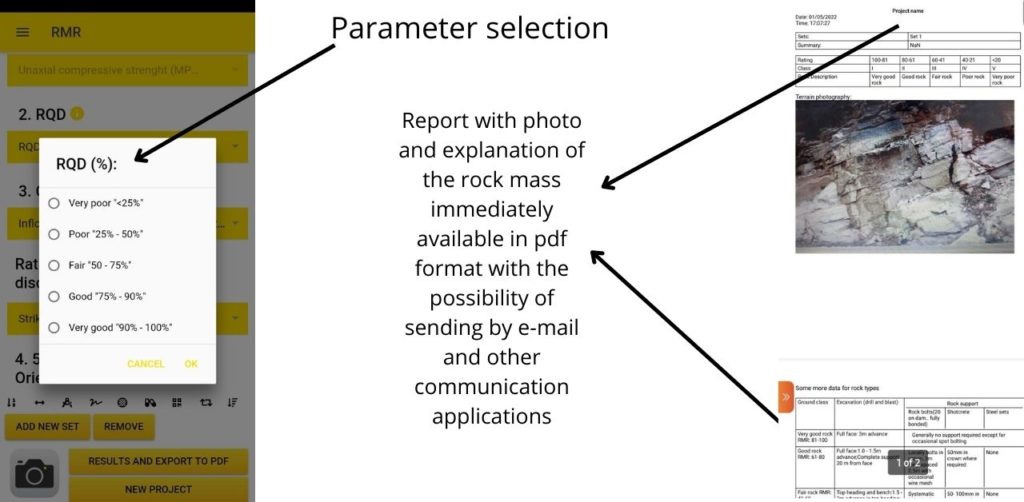

Below we will present the possibilities of the application:

The photo above shows adding the project name, then selecting the rock mass parameters using the drop-down menu, and photographing the rock mass.

The application provides the ability to quickly calculate the RMR on the spot with your mobile device, after the calculation you can send the report via communication applications, which facilitates communication and delivery of reports from the spot.

Rock mass rating application is available on the Google play store, when you download the application you can start working immediately without any restrictions. We use it every day and we are very satisfied, we go to the field without additional papers. Also, a large number of geologists / geotechnicians around the world use this application with great pleasure.

Rock Mass Rating mobile application download

You can download the Rock Mass Rating application by clicking on the following photo.