Introduction

In the ever-evolving field of geology and engineering geology, tools and techniques play a pivotal role in understanding geological formations, assessing rock strength, and making informed decisions in construction projects. One such indispensable tool is the Schmidt Hammer, which has gained prominence in recent years. In this comprehensive guide, we will delve into the world of Schmidt Hammer, its applications, benefits, and how it revolutionizes geoscientific research.

What is a Schmidt Hammer?

A Schmidt Hammer, also known as a Swiss Hammer or Rebound Hammer, is a handheld and non-destructive testing device used in the field of geology and engineering geology. Its primary purpose is to assess the surface hardness of various materials, including rocks and concrete.

The Schmidt Hammer operates on the rebound principle, where it impacts the material’s surface with a small hammer and measures the rebound velocity to calculate a numerical value known as the “rebound value” or “Schmidt rebound number” (R-value).

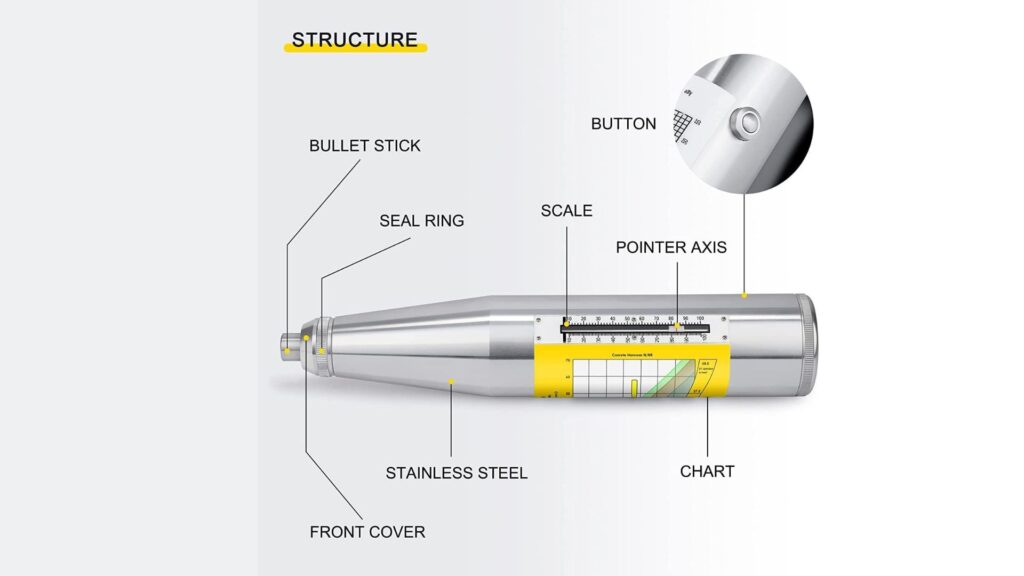

The key components and features of a Schmidt Hammer include:

Impact Hammer: This is the part of the device that strikes the material’s surface. It has a consistent mass and impact energy.

Sensor: The Schmidt Hammer is equipped with a sensor that measures the rebound velocity of the hammer after impact.

Display: The device displays the rebound value, which is a numerical representation of the material’s surface hardness.

The Schmidt Hammer is used in a variety of applications, such as:

Rock Strength Assessment: Geologists and engineers use it to determine the compressive strength of rocks, which is essential for geological research and construction projects.

Concrete Quality Assessment: It is employed to evaluate the quality and durability of concrete structures, including bridges, dams, and buildings.

Tunnel and Mining Safety: Engineers use it to assess the stability of tunnels, mines, and underground excavations.

Historical Monument Preservation: Conservationists use the Schmidt Hammer to test the structural integrity of historical monuments and sculptures to guide preservation efforts.

Geotechnical Investigations: It supports geotechnical investigations by providing data on the mechanical properties of soil and rock formations.

How to Use a Schmidt Hammer?

Using a Schmidt Hammer correctly is crucial for obtaining accurate and reliable measurements of the surface hardness of materials such as rocks and concrete. Here are step-by-step instructions on how to use a Schmidt Hammer effectively:

Calibration:

Before using the Schmidt Hammer, ensure that it is properly calibrated. Calibration is essential to ensure accurate measurements. Follow the manufacturer’s instructions for calibration, as different models may have specific calibration procedures.

Surface Preparation:

Ensure that the material’s surface you intend to test is clean, dry, and free from loose particles or debris. Remove any loose material from the testing area to ensure a consistent and accurate reading.

Safety Precautions:

Wear appropriate personal protective equipment (PPE) such as safety glasses and gloves, especially if working with potentially hazardous materials.

Hold the Schmidt Hammer:

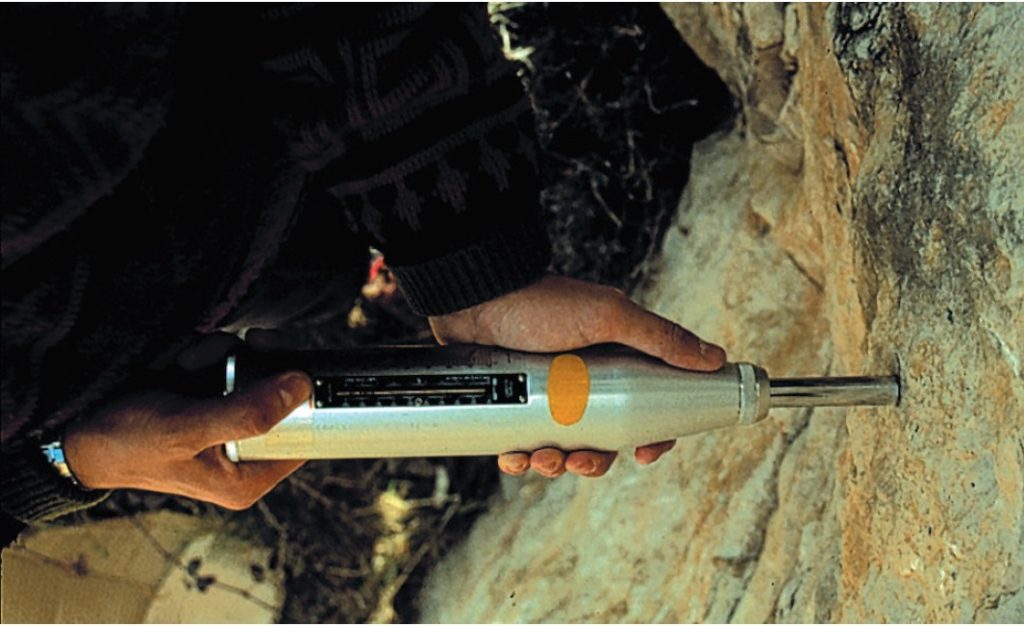

Hold the Schmidt Hammer firmly in your dominant hand, ensuring a stable grip.

Positioning:

Position the Schmidt Hammer perpendicular to the surface of the material you are testing. It’s essential to maintain a 90-degree angle between the device and the material to ensure accurate results.

Impact:

Firmly press the Schmidt Hammer against the material’s surface and trigger the device to release the hammerhead. The hammerhead will strike the surface with a predefined amount of energy.

Rebound Measurement:

After impact, the hammerhead will rebound off the material’s surface. The Schmidt Hammer is equipped with a sensor that measures the rebound velocity of the hammerhead.

Record the Rebound Value:

The Schmidt Hammer will display a numerical value, often referred to as the “rebound value” or “Schmidt rebound number” (R-value). This value represents the surface hardness of the material. Record this value.

Repeat Measurements:

For accurate results, take multiple measurements at various locations on the material’s surface. A minimum of three measurements per test point is recommended. Calculate the average of these measurements to reduce variability.

Interpretation:

Compare the obtained R-values with reference values or standards relevant to your specific application. Different materials may have different acceptable hardness levels.

Documentation:

Keep detailed records of the measurements, including the location, date, and any relevant notes. Proper documentation is essential for future reference and analysis.

Cleanup:

After completing your measurements, clean the Schmidt Hammer and store it in a safe and secure place, following the manufacturer’s guidelines.

It’s important to note that the accuracy of Schmidt Hammer measurements can be influenced by various factors, including the material’s surface condition, operator skill, and calibration. Therefore, it’s crucial to follow best practices and standards when using this tool to ensure reliable and meaningful results.

Comparing Schmidt Hammer to Other Geotechnical Tools

When evaluating geotechnical properties and conducting field assessments, various tools are available to geoscientists and engineers. The choice of tool depends on the specific needs of the project and the properties being investigated. Let’s compare the Schmidt Hammer to other common geotechnical tools, such as the Point Load Tester and Ultrasonic Pulse Velocity Tester:

| Parameter | Schmidt Hammer | Point Load Tester | Ultrasonic Pulse Velocity Tester |

|---|---|---|---|

| Type of Test | Surface Hardness | Point Load Strength | Velocity of Stress Waves |

| Non-Destructive Testing | Yes | No | Yes |

| Portability and Ease of Use | High | Moderate | Moderate |

| Depth of Penetration | Surface Only | Surface Only | Varies |

| Material Compatibility | Rocks, Concrete | Rocks | Concrete, Rock, Soil |

| Calibration Required | Yes | No | Yes |

| Measurement Time | Instantaneous | Moderate | Moderate |

Schmidt Hammer:

- Type of Test: It assesses the surface hardness of materials like rocks and concrete.

- Non-Destructive Testing: The Schmidt Hammer provides non-destructive testing, meaning it doesn’t damage the material being tested.

- Portability and Ease of Use: It is highly portable and user-friendly, making it suitable for fieldwork and on-site assessments.

- Depth of Penetration: It only assesses the hardness of the material’s surface.

- Material Compatibility: The Schmidt Hammer is primarily used for rocks and concrete.

- Calibration Required: Calibration is necessary for accurate results.

- Measurement Time: It provides instantaneous measurements.

Point Load Tester:

- Type of Test: It measures the point load strength of rock and similar materials.

- Non-Destructive Testing: Point Load Testing is a destructive method as it involves fracturing a small core specimen.

- Portability and Ease of Use: It is moderately portable, but the testing process can be more complex compared to the Schmidt Hammer.

- Depth of Penetration: Like the Schmidt Hammer, it assesses the material’s surface.

- Material Compatibility: It is specifically designed for testing the strength of rocks.

- Calibration Required: Point Load Testers typically do not require calibration.

- Measurement Time: Point Load Testing requires a moderate amount of time to perform.

Ultrasonic Pulse Velocity Tester:

- Type of Test: It measures the velocity of stress waves in materials like concrete, rock, and soil.

- Non-Destructive Testing: Like the Schmidt Hammer, it provides non-destructive testing.

- Portability and Ease of Use: It is moderately portable and requires some expertise for accurate measurements.

- Depth of Penetration: The depth of penetration varies depending on the material and testing conditions.

- Material Compatibility: It can be used for a wider range of materials, including concrete, rock, and soil.

- Calibration Required: Calibration is necessary for precise velocity measurements.

- Measurement Time: Ultrasonic Pulse Velocity Testing typically requires a moderate amount of time for data collection.

In summary, each of these geotechnical tools serves specific purposes and has its advantages and limitations. The choice of tool depends on the project requirements and the properties of the materials being assessed. The Schmidt Hammer, with its non-destructive nature and portability, is particularly well-suited for quick surface hardness assessments in the field.

Conclusion

In conclusion, also known as the Swiss Hammer or Rebound Hammer, is a remarkable geotechnical tool that has become indispensable in the fields of geology and engineering geology. Its principle of operation, based on the rebound of a hammerhead, allows for non-destructive and rapid assessments of the surface hardness of materials, including rocks and concrete. This versatile tool offers several key advantages, such as portability, ease of use, and the ability to provide instantaneous measurements.

The Schmidt Hammer finds extensive applications in a variety of fields, from assessing rock strength for geological research to evaluating the quality and durability of concrete structures in construction projects. Its non-destructive nature makes it particularly valuable when preserving historical monuments or ensuring the safety of tunnels and mines.

However, it’s essential to be aware of the Schmidt Hammer’s limitations, such as its sensitivity to surface conditions and the need for proper calibration and operator skill to obtain accurate results.

In summary, the Schmidt Hammer is a valuable asset in geotechnical investigations, offering a quick and cost-effective means of assessing material hardness in the field. As technology continues to advance, we can anticipate further improvements in Schmidt Hammer technology, further enhancing its utility in geoscientific research and engineering projects.

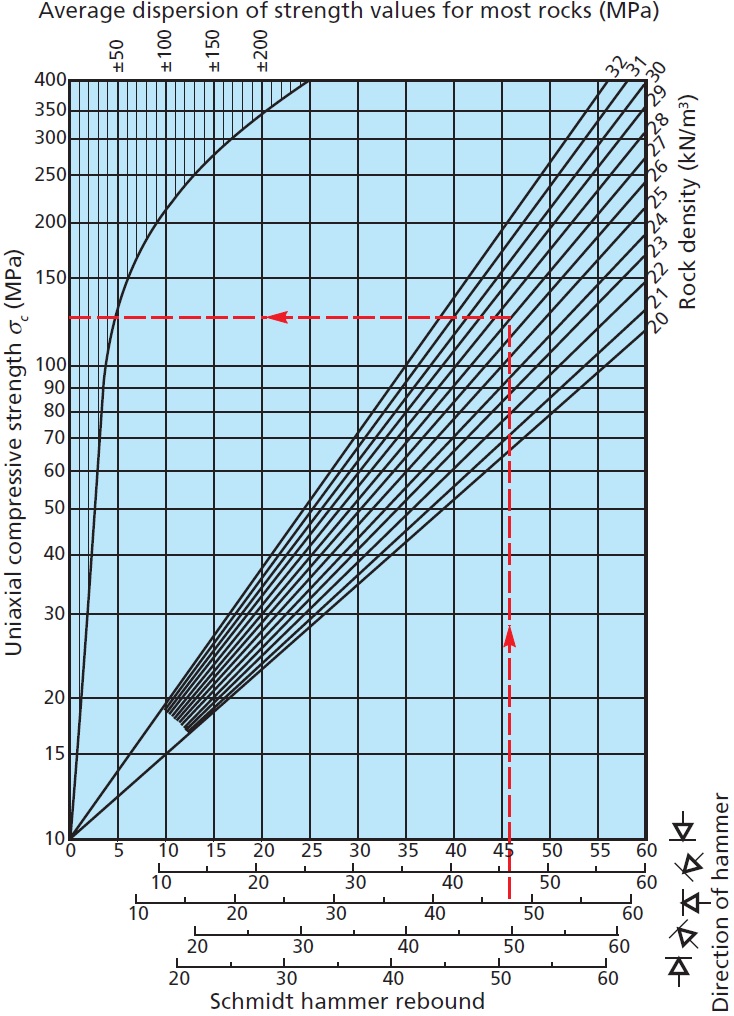

Uniaxial strength assessed using the Schmidt hammer

Guest author of the article: Mirza Djedović, B.Sc. geology