Water-Level Dipper

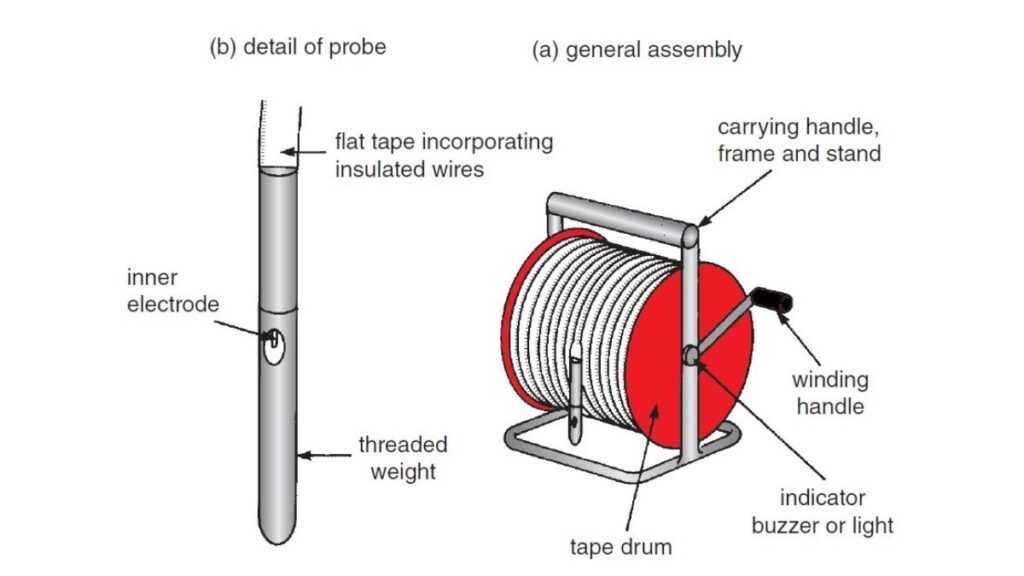

Water-Level Dipper consist of a lat tape graduated in metres and wound on to a drum.Wires run down each side of the tape and are attached to a probe that senses the water surface by completing a circuit, causing a buzzer to sound. Figure 1 shows the main features of such a typical dipper.

What do Water-Level Dipper consist of?

Most commercially available dippers are made on the same general format. Batteries (usually totalling 9 volts) are housed in the drum spindle, which also contains electronic circuitry. The probe is made of stainless steel and acts as an electrode, with a second inner electrode being a pointed steel rod visible through holes in the weighted end. The electrodes are connected by a pair of wires that are incorporated into each edge of the plastic tape. When the point touches the water surface a circuit is completed and a buzzer sounds.

The size of Water-Level Dipper?

This equipment allows quick and easy readings to be taken, and the tape can be read to the nearest half centimetre if required. Some dippers have tapes graduated in millimetres, although ield measurements to this accuracy are rarely achieved in practice. Dippers come in a wide range of sizes, from a compact 10 m up to an enormous 500 m length!

What size Water-Level Dipper should I get?

When purchasing a dipper, ensure that it is long enough to measure the deepest water table in your area, bearing in mind that pumping-water levels in abstraction boreholes are much deeper than rest-water levels. A dipper 100 m long will cater from most situations, but 200-m tape may be required for measuring some pumping levels in boreholes with large drawdowns. If you are studying a shallow aquifer where there are only hand-dug wells, a 10-m dipper should be adequate. It is important to make these considerations as the size of the dipper affects the cost, and if you can get away with a small one they are very much more convenient to carry and use. Some modern dippers also incorporate other measurements such as electrical conductivity and temperature.

Some dippers have round section cable, with the depth graduations marked in metres by adhesive bands. It is necessary to use a steel tape to measure the distance in centimetres (i.e. to the nearest 0.01 m) from the nearest metre mark to obtain a more precise water-level reading. These instruments are not easy to use and are hopeless for pumping tests, where frequent measurements are required.

Using a Water-Level Dipper

Lower the probe down the well or borehole until it hits the water, when the buzzer will sound. When this happens, pull the tape back slowly out of the water until the signal stops. Repeat the exercise several times to enable you to ‘feel’ the water surface. It is conventional to take the point where the buzzer stops as being the water level. Use your ingers to mark the position on the tape against a fixed datum point such as the top of the casing, and then read off the level to the nearest centimetre. When using a dipper with a cable marked off in metres only, use a steel tape to measure the distance from your inger to the nearest metre mark below the place you are pinching, and add the two values together.

Record the dipped level and time of measurement and make a note of the datum used. It is good practice to repeat the reading after you have written it down, as a check. It is a good idea to mark the datum point with coloured paint if you expect to take other readings in the same well.

Test the dipper each day before you go into the ield by unscrewing the weighted end of the probe to expose the inner electrode, and then complete the circuit either by using the weight to short out the contacts or by immersing the end in water.

A commonly used alternative is to wet the ingers with spittle to do the same job, but this is not good practice. If the buzzer does not work check the batteries, and should these be working inspect the cable for breaks. The first 30 m of cable gets most wear, and so the insulation can be rubbed off as the tape is lowered over sharp edges such as the top of the casing. Try to reduce this wear as much as possible by running the tape over softer materials such as a piece of wood or your hand. If the insulation is worn through to the wires they may break, thereby preventing the circuit from being completed. Do not be tempted to cut off the damaged section and reconnect the probe, otherwise you will always have to remember to deduct a constant length from your readings and errors will inevitably occur. Occasionally, the circuitry inside the drum may be faulty and will need checking and repair by an electronics expert. It is worth remembering that dippers will not work in groundwater with a low conductivity.

You may also need to measure the total depth of a well or borehole. There are commercially available total depth probes that consist of a weight (about 0.5 kg) attached to a length of steel wire cable marked off in metres. To measure the depth of the borehole, lower the probe until you feel the weight ‘come off’ the cable when it reaches the bottom of the well. Improvised total depth probes can be made using a length of string and a weight, but make sure that the string is sufficiently strong and the weight is not too bulky to it easily in the borehole and is not made of material that could pollute the water. A weight tied to the probe of a dipper will also work, but the high water pressure at the base of the borehole may damage the seal on the dipper and so is not recommended.