What is a Tilt test?

Tilt test is used to estimate the angle of friction of discontinuities or basic angle of friction for smooth discontinuities to allow calculation of the residual angle of friction and joint roughness coefficient (JRC).

How is the Tilt test performed?

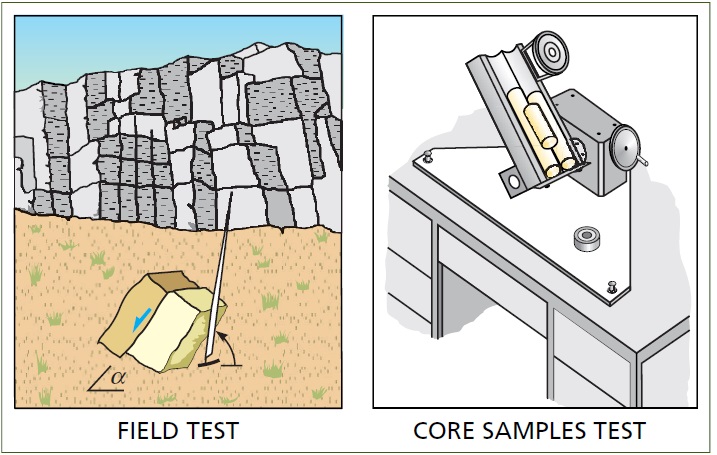

A sample rock block containing a non-cohesive discontinuity plane is required to estimate the angle of friction in discontinuities. The rock sample is placed on an adjustable testing plane, separated along the surface where the roughness is to be measured. Then the plane is slowly tilted until the sample starts to slide. As soon as this occurs, the angle of the support plane is measured in relation to the horizontal, α, (Figure 1).

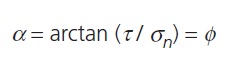

The procedure should be repeated with several rock samples. The value of α is a function of the ratio between the shear stress and normal stress acting on the discontinuity:

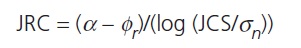

The JRC value of the discontinuity is obtained from α. This is needed to apply the Barton and Choubey criterion, to estimate the shear strength of rough discontinuities:

Performing the Tilt test in the laboratory

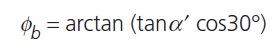

The test can also be carried out in the field or the laboratory using three cylindrical core samples. Two parallel cores are placed together on a horizontally supported surface with a third core lying on top of them. The support base is gradually tilted until the upper core slides along the two lower samples. This gives the angle α’ and φ can be obtained using cylindrical cores of the same diameter, because the friction angle is α’. The following expression is used to assess the basic friction angle:

The basic angle of friction of the material, φb, corresponds to the strength of smooth, flat, non-weathered discontinuities. From this parameter and data obtained with the Schmidt hammer, the residual angle of friction, φr, can be calculated using Barton and Choubey’s expression.