Borehole drilling

Geotechnical drilling is normally small in diameter and are made with lightweight, versatile, easily transported equipment. They can be drilled to a depth of around 100 m, after which heavier equipment is used.

They can drill through any type of material and samples can be extracted for testing and the ground tested inside them. Boring procedures depend on the type of material and the type of sampling and testing to be done. The most common procedures are rotary, auger and percussion drilling.

Rotary drilling

Rotary drilling can penetrate any type of soil or rock at any angle of inclination and to considerable depths. They are not usually deeper than 100 m for geotechnical purposes although they may be as deep as 500 m.

Core extraction is a continuous process and can give a very high percentage of core recovery in relation to the length drilled, depending on the drilling system used. Some types of materials, such as gravels and boulders, or fine sands below the water table, are difficult to recover with rotary drilling, due to erosion by the drilling fluid.

Rotary drilling uses the following elements housed in the barrels: the drill head, core barrel, core catcher and drilling bit.

The drill head is the part that joins the core barrel, where the sample is collected, and the drill rods that transmit the rotary movement and force exerted by the drilling machine.

The core catcher houses a catcher spring that opens like an iris when core passes through it and grips core to prevent it from slipping as the core barrel is withdrawn from the hole.

The actual perforation is done by the drill bit. The cutting edge may be tungsten carbide or diamond. Tungsten carbide bits are used for softer rocks and soils. Diamond bits must be used for hard or very hard rocks.

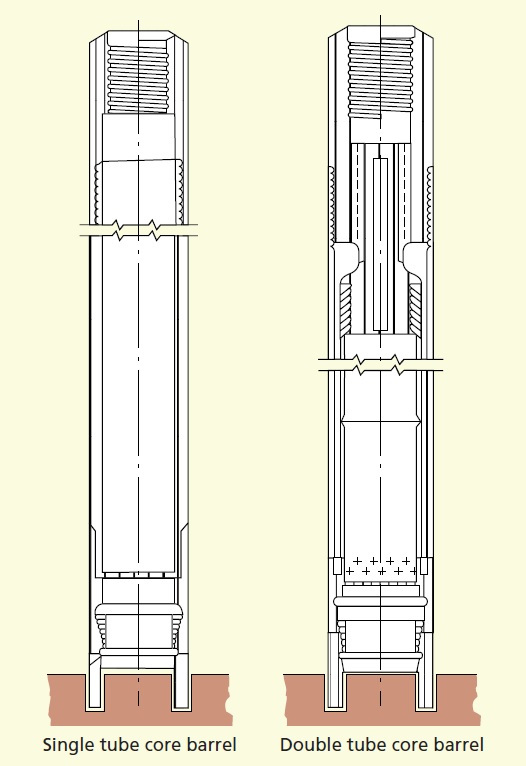

Core barrels may be single or double Tubes. In the single tube core barrel, drilling fluid passes over the whole surface of the sample (Figure 1).

This effect, and the rotation of the tube, may lead to the disintegration of partially cemented soils or softer rocks. For this reason, the single tube is used when high recovery is not required. If high recovery is required, a double tube core barrel is used, where water runs down the annulus between the tubes, and contacts with the sample only at the base of the tube where it joins the core bit.

The inner tube is mounted on bearings so that it is almost stationary while the outer tube rotates. The damaging effect of drilling fluids may be further reduced by using a triple tube core barrel; the sample here is sheathed in a third tube housed inside the double tube.

This tube can extend a short way beyond the bit of the rotating outer tube and pierces the ground with a cutting shoe that retracts or extends depending on how compact the ground is.

These barrels are generally used where the drilling depth does not exceed 100 m. For greater depths a wireline system is more appropriate for brining sample barrels to the surface, as this considerably reduces operating time and offers better performance.

Rotary core drilling can be carried out with a flushing medium such as water or bentonite slurry or compressed air, even though there may be water or mud present on the drill rig. The flow is generally direct, with downward flow through the rods; it can also be reverse, in which case a special system of rods is required.

To obtain the best results and performance, the operating techniques must be adapted to the type of material being drilled and the most suitable types of drill, barrel and core bit for it selected.

Rotation velocities, pressures exerted on the bit and the operating torque must also be appropriate for the material being drilled, making the success of such drilling very dependent on the skill and experience of the driller and the condition of the equipment used.

In deep boreholes, any deviation must be controlled from the planned direction, caused by the tendency of the borehole to follow the dip of different layers or strata.

Auger drilling

Auger drilling is suitable for relatively soft and cohesive soils and unsuitable for hard or consolidated soils. Its advantages include low cost, portability and rapid installation of the equipment.

Boreholes of this type often do not allow precision better than 0.50 m in defining the depth of different layers encountered. Samples obtained from auger drilling will be disturbed, although, as described below, it is possible to obtain undisturbed samples with certain types of sampling devices.

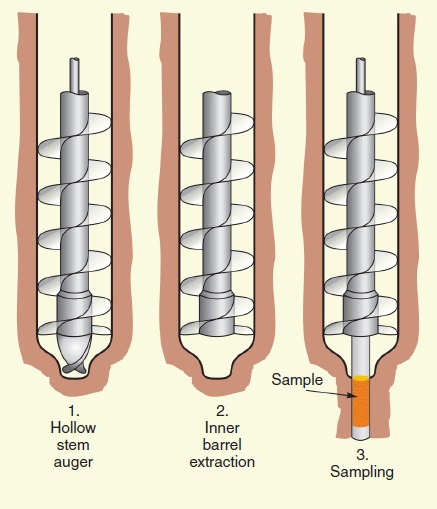

Auger drilling can be done by hand for shallow depths (2–4 m) and small diameters (2–5 cm), or by power equipment for depths of up to 40 m with diameters from 7 to 20 cm. It is usually done for preliminary survey purposes (Figure 2).

There are two types of augers: hollow and flight. Flight augers have a helical thread. With the hollow type, undisturbed samples can be obtained without having to extract the flight to the surface. The shaft of the flight is slightly larger than for a flight only drill, so that it can contain a central casing that ends in a small drill bit at the helical head of the flight and turns simultaneously with it. These are removed from the inside of the shaft and a sampler inserted (Figure 3).

Percussion drilling

Percussion or shell and auger drilling allows soils with a firm or very firm consistency to be bored and is therefore used in both granular and cohesive soils. Boreholes of this type can reach depths of up to 30 or 40 m, although depths of 15 to 20 m are the more usual. Boring is carried out by driving a series of steel tubes into the ground with a 120 kg hammer that drops from a height of 1 m.

The number of blows needed to penetrate each 20 cm section must be counted systematically in order to determine the compactness of the soil. The barrel used, which may have outside diameters of 91, 128, 178 or 230 mm, acts as a shoring mechanism during the extraction of samples, which is carried out using clay cutters and shells.

Special boreholes

In addition to the methods already described, drilling is sometimes carried out with drill bits, impact hammers or rotary percussive drill, or by using tricone rollers. These techniques are known as destructive drilling because, instead of a core sample, they produce rock chips and pulverized material which is expelled up the borehole by the drilling fluid.

Methods used will depend on the type of ground to be drilled and the purpose of the investigation. Destructive drilling is used to penetrate boulders and loose blocks. Rotary percussive drilling can be used to detect cavities in limestones, volcanic rocks or abandoned mines.

Number and depth of boreholes

Deciding on the number and depth of boreholes is one of the basic questions in planning site investigations, and is dependent on several factors. As a guideline, a borehole should reach the level of the deepest substratum that may be affected by any structural action on the ground (loads, seepages, deformations, etc.). The number made will depend on both the aims and scope of the site investigation and the extent to which each borehole is representative of the area involved.

Borehole data presentation

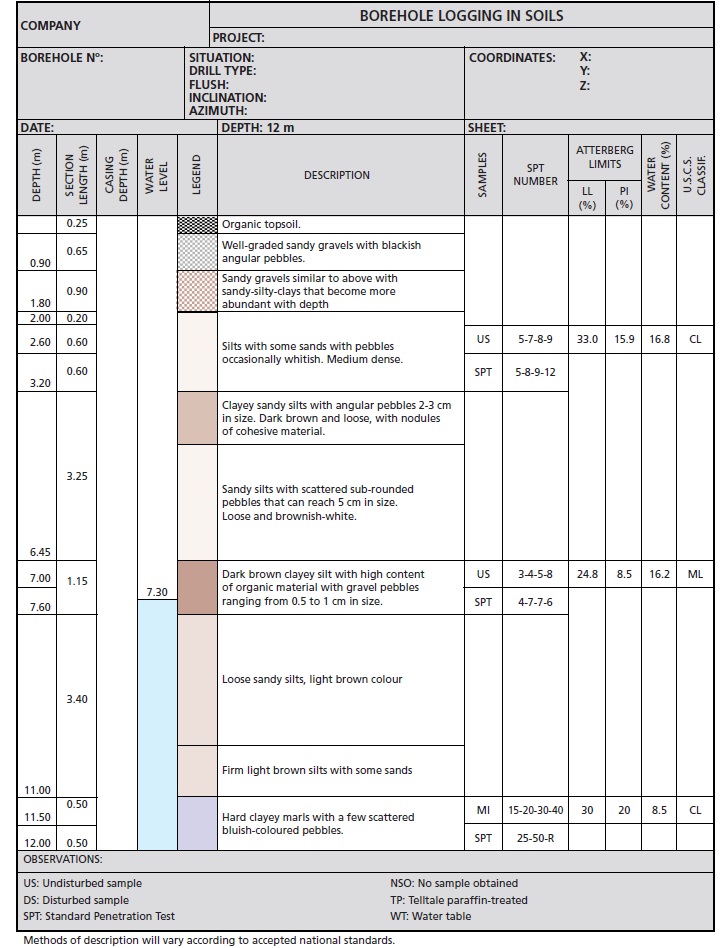

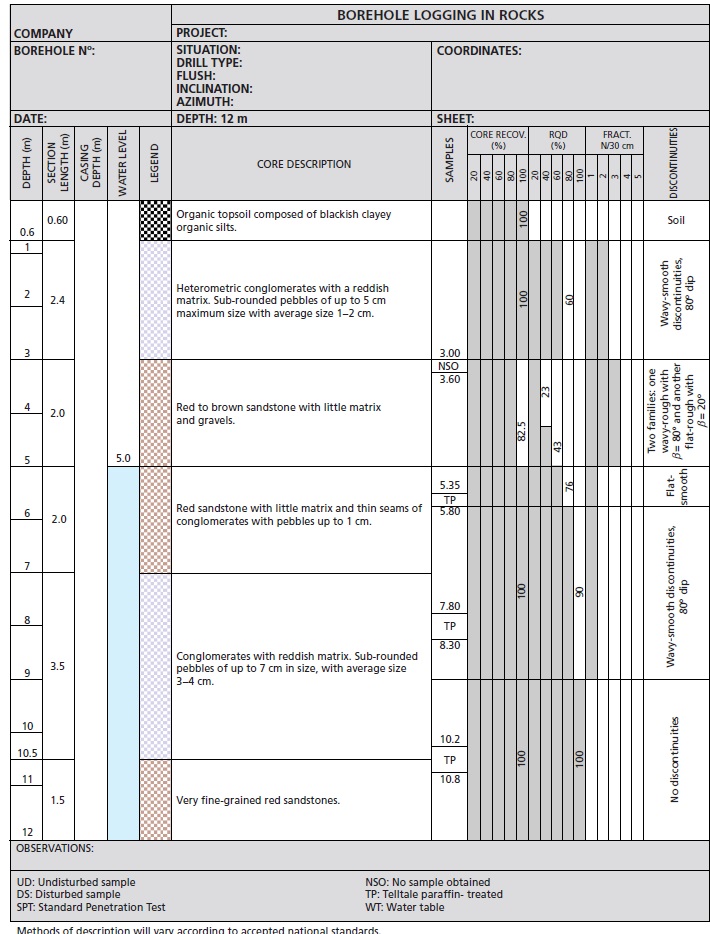

The results of borehole investigations are presented on field data sheets together with geotechnical data obtained from logging (Figures 4 and 5). It is usual for a country to adopt a certain standard method of description, e.g. Eurocode 7, or the ASTMS of the United States, and these should be followed when requested to do so.

[…] main methods for investgating landslides and for general control of transversal displacements in boreholes. Inclinations at various points inside a borehole are measured by means of a sonde that transmits […]

[…] 0.5 kg) attached to a length of steel wire cable marked off in metres. To measure the depth of the borehole, lower the probe until you feel the weight ‘come off’ the cable when it reaches the bottom of […]